Two workers recently were killed in accidents that occurred during the de-watering of natural gas pipelines, a process conducted following the construction of the pipelines. The victims were killed when they were struck by temporary de-watering piping, which was not properly anchored and broke loose from its coupling from excessive air pressure. The Occupational Safety and Health Administration (OSHA) and the Office of Pipeline Safety (OPS) urge that all persons working on, or in close proximity to, de-watering processes be alerted to this serious hazard and take appropriate steps to prevent death or serious injury.

Purpose

The purpose of this Safety and Health Information Bulletin (SHIB)/Advisory Bulletin (ADB) is to highlight:

- potential hazards associated with pipeline de-watering operations;

- work practices and guidelines that can reduce the potential for unexpected separation of temporary de-watering pipes; and

- training that can help to protect employees from these hazards.

Accident Description

The OSHA Allentown and Wilkes-Barre Area Offices recently investigated two fatalities that occurred in conjunction with de-watering processes associated with newly constructed natural gas pipelines. In both cases, the temporary de-watering piping violently separated from its couplings, striking and fatally injuring employees. In one instance, the separated section of pipe was thrown 45 feet from where it had been attached to the temporary de-watering valve. OSHA determined that a major contributing factor to both of the accidents was temporary de-watering pipelines that were not adequately secured to prevent the piping from moving or separating. In one case, the failure occurred at a pipe coupler that was not being used within the safe tolerances established by the manufacturer.

Background

After a pipeline is laid, a hydrostatic test is conducted to ensure its integrity. Hydrostatic testing may also be conducted during the service life of the pipeline to evaluate its operational integrity.

The hydrostatic test consists of pumping water into the pipeline, “pressuring up” the line to specified test pressures, and holding that pressure for a discrete period of time in accordance with applicable regulations and guidelines, including regulations promulgated by OPS. After completion of the hydrostatic test, the pressure is relieved and the water is removed from the pipeline (de-watering).

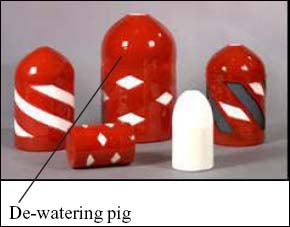

The de-watering process involves connecting a temporary de-watering line (figure 1) to the main pipeline with mechanical couplers and adequately securing the temporary de-watering line to prevent displacement. A de-watering “pig” (figure 2) is then forced through the main pipeline using several hundred pounds pressure of compressed air. As the pig is forced through the pipeline with air pressure, the water remaining in the line from hydrostatic testing is pushed out of the main pipeline through the temporary de-watering line.

OPS regulates pipeline safety, recognizes the existence of hazards associated with testing pipelines, and requires operators to protect their employees and the public during hydrostatic testing. 49 CFR 192.515(a) states that “each operator shall insure that every reasonable precaution is taken to protect its employees and the general public during the testing [required before natural gas pipelines are placed into service or when pipelines are retested to confirm operational integrity].” 49 CFR 195.402(c) requires each pipeline operator to prepare and follow procedures for safety during maintenance and normal operation.

Although OSHA has no specific regulations addressing the design or securing of de-watering piping systems, the Agency is aware of workplace injuries and fatalities caused by improper anchoring or restraining of temporary de-watering pipes. OSHA’s authority is limited by Section 4(b)(1) of the Occupational Safety and Health Act (OSH Act), which precludes OSHA from regulating working conditions over which other federal agencies “exercise statutory authority to prescribe or enforce standards or regulations affecting occupational safety or health.” 29 U.S.C. 653(b)(1). Thus, OSHA’s authority to address occupational safety and health hazards associated with pipelines is controlled by the scope and nature of OPS regulations. In practice, OSHA authority over working conditions associated with pipeline de-watering operations generally is limited to employers (e.g., contractors hired by pipeline operators), and their workers, who are not covered by OPS regulations

Description of Hazards

Lack of Anchoring

The potential for separation of a pressurized pipeline is a recognized hazard in related industries and applications. The oil and gas industry has long recognized this hazardous condition in several operations, and there are published consensus industry standards addressing the potential for such failure [1,2,3]. These standards recommend the securing or anchoring of pressurized flow, bleed-off, and blow-down lines to prevent movement. Persons experienced with hydrotest de-watering processes also recognize this potential hazard, and it is accepted industry practice to adequately anchor or secure de-watering pipe to prevent pipe movement, separation, and/or whipping.

Worn Couplings

The condition of the couplings, which are used to attach the de-watering pipe to the main gas line and other temporary de-watering pipe sections, likely contributed to one of the accidents that OSHA investigated. In that case, the failure occurred at a pipe coupler that was not within the manufacturer’s established tolerances. With the added pressure of the de-watering process, a damaged or improper coupler could contribute to the separation of temporary pipe sections. It is imperative that all connections and fixtures be in proper working condition. The groove installed on the pipe needs to be conformed to manufacturer specifications and guidelines, be properly fitted, as specified by the engineer who develops the de-watering plan, and chosen for the application.

Excessive and Variable System Pressures

During de-watering, the de-watering pig is pushed through the pipeline using compressed air. The pressure exerted on a piping system, including the de-watering piping, can be much greater than that indicated by gauges on the air compressor(s). Where terrain includes hills, slopes, or other changes in elevation, the pressure on the de-watering system can be increased significantly by the hydrostatic head pressure, adding to the potential for pipe separation.

It is possible for the pig to become stalled or stuck in the line. Whether the pig becomes stalled because of air flow around the pig or stuck because of debris inside the pipe or faulty seals, freeing the stuck pig can be problematic. At times, workers will use increased air pressure to attempt to move the pig. While increasing the line pressure is an accepted practice, the safe pressure limits of the pipeline and connections must never be exceeded. If the pressure limits of the main piping or de-watering systems are exceeded, there may be a catastrophic failure of the pipe, or more likely, the pipe connections.

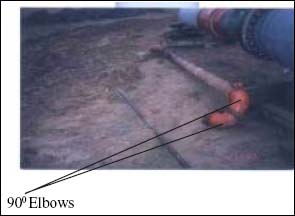

Fittings, such as elbows (figure 6) in piping systems, and other factors also can contribute to pressure variation as the pig passes through the piping. Forces associated with those pressure changes can be transferred to temporary piping systems and cause movement and ruptures in connections and piping. Employers should consider the forces involved, and they should design and install anchoring systems to properly restrain or control de-watering piping.

Lack of Training

It is imperative that employers train employees who perform or work near hydrotest de-watering operations. Employers engaged in construction activities are required by the OSHA standards to “instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.” 29 CFR 1926.21. Employers need to ensure that employees involved in de-watering of pipelines understand the potential hazards of the pressurized lines and the precautionary measures and controls necessary to protect themselves and others working in the vicinity.

Exclusion Zone

During the testing and de-watering processes, there may be hazards that may not have been completely controlled. This might include the possibility of unexpected high pressure in the pipe from internal malfunctions or irregularities, as well as failure of the pipe itself under full test pressure from undetected imperfect welds. Such situations may exceed the designed capacities of the anchorages. Therefore, the access to the test zone may be limited to only those persons who are necessary to perform the test.

Conclusions

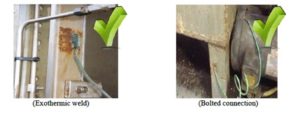

It is recognized industry practice to anchor or restrain de-watering piping in order to prevent death or serious injury from de-watering pipeline separation. Complete engineering analyses should be performed to determine requirements for the installation and use of de-watering systems. Engineering designs and installation techniques should be developed for these temporary pipelines. In addition, employees installing temporary pipelines should be trained in these designs and techniques, and they should follow them when installing these temporary systems. Employers also should ensure that couplings and piping systems are sound and can withstand the pressures involved.

Recommendations

While there is no specific OSHA standard addressing de-watering of pipelines, the Occupational Safety and Health Act requires employers to provide a workplace that is “free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees.” 29 U.S.C. 654(a)(1). To this end, employers need to ensure that proper procedures are followed and that employees who perform de-watering processes are adequately trained and knowledgeable about proper procedures for restraining or anchoring of de-watering lines. The following guidelines will help reduce the risk of injury to employees involved in de-watering activities:

- Study the piping system. During the initial planning stage of a de-watering operation, an engineering analysis of the existing and temporary piping system should be performed to identify the pressure associated with fluids and other forces that could adversely affect the integrity of the pipeline or the stability of the drainage and its components. The employer should design the de-watering system and develop installation techniques based on the expected forces of the particular project. Alternatively, designs and techniques could be developed for a “worst case” scenario that could be applied to all de-watering projects.

- Anchor the de-watering lines. It is accepted industry practice to adequately anchor or secure de-watering piping to prevent movement and separation of the piping. Employers should establish effective anchoring systems based on expected forces and ensure that the systems are used during de-watering projects.

- Ensure condition of couplings and parts. All couplings and parts of the de-watering system need to be properly selected for their application. The associated piping which the couplings connect is a significant variable in the entire mechanical piping system. The couplings are manufactured in a controlled environment, and variations in the quality of the couplings should be limited. Employers should ensure that couplings are within manufacturer’s tolerances and free of damage that may result in connection failure. A chain is only as strong as its weakest link – in de-watering piping systems, the weakest link frequently is the temporary de-watering pipe connections.

- Provide adequate employee training. This training should instruct employees on de-watering installation designs and techniques, including proper coupling and anchoring methods. Employers need to ensure that employees understand the potential hazards of improperly installed de-watering systems, provide employees a means of determining whether the pipe groove meets manufacturer’s tolerances, and the procedures they should implement to protect themselves and others working around them.

- Proper Procedures. Employers should ensure that proper installation and de-watering procedures are followed on the job site.

To acknowledge reading this incident review please leave a comment or discuss incident or add hazard.

References

- American Petroleum Institute (API). Recommended Practice for Occupational Safety for Oil and Gas Well Drilling and Servicing Operations. API RP 54-1999, Section 12.4.3.

- American National Standards Institute (ANSI). Power Piping. ANSI B31.1-1973, Section 121.2.

- U.S. Army Corps of Engineers (USACE). Safety and Health Requirements Manual. EM 285-1-1, 1996 Section 20.

- Federal Pipeline Safety Regulations. 49 CFR Part 192 & Part 195.

More info: https://www.osha.gov/dts/shib/shib062104.html